Question: How can I ensure consistent quality standards in my precision machining plant, especially in industries where defects are costly?

Cerelyze

For maintaining quality standards across your precision machining plant, Cerelyze is a great option. This AI-based visual inspection system uses a smart camera to detect defects like porosity, nicks, dings and burrs more accurately than human inspectors. By automating inspections, Cerelyze eliminates human error and fatigue, increasing productivity and lowering potential downtime, which is critical in industries where defects can be catastrophic.

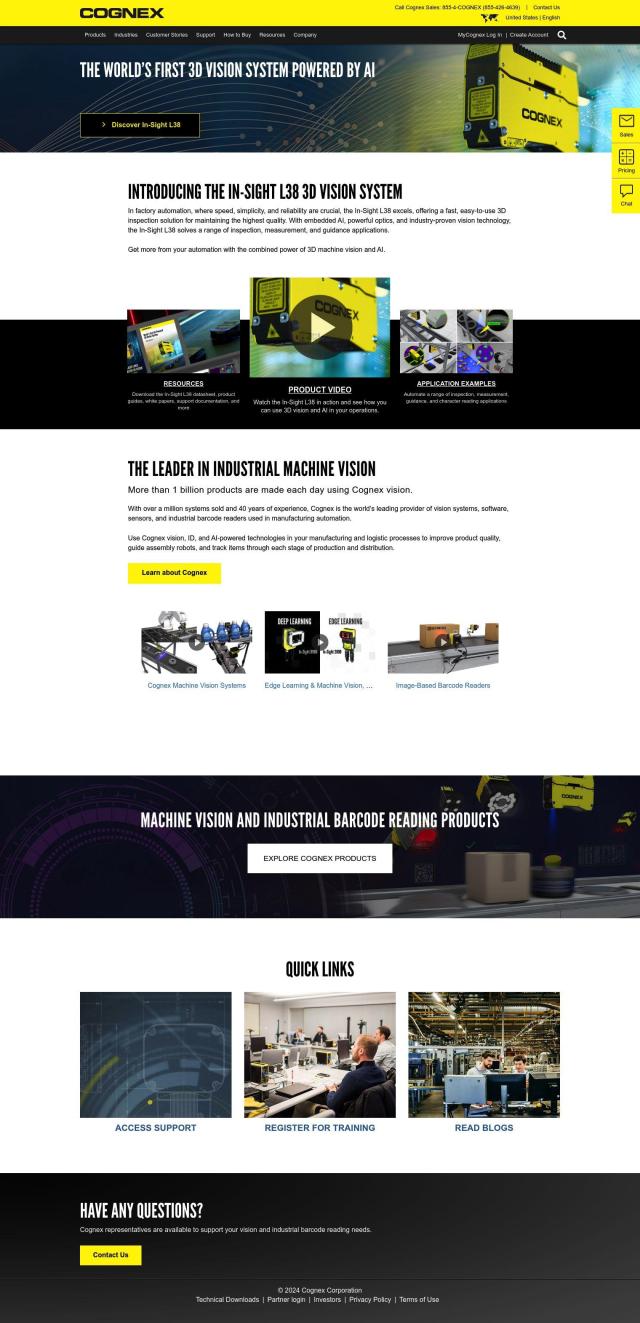

Cognex

Another option is Cognex, which makes a variety of machine vision and barcode scanning products to help improve quality and efficiency. The In-Sight L38 is a 3D vision system that uses AI to accelerate and simplify 3D inspection, measurement and guidance tasks. Cognex products are used in manufacturing, logistics and automotive industries to reduce defects and lower costs while maximizing production.

LandingLens

For a more complete solution, check out LandingLens. This cloud-based computer vision software platform uses deep learning and domain-specific Large Vision Models (LVMs) to help with a wide range of challenges. LandingLens lets customers create and train their own LVMs using proprietary imagery, and it offers flexible deployment options and continuous learning abilities, making it a good fit for improving quality control in precision machining.