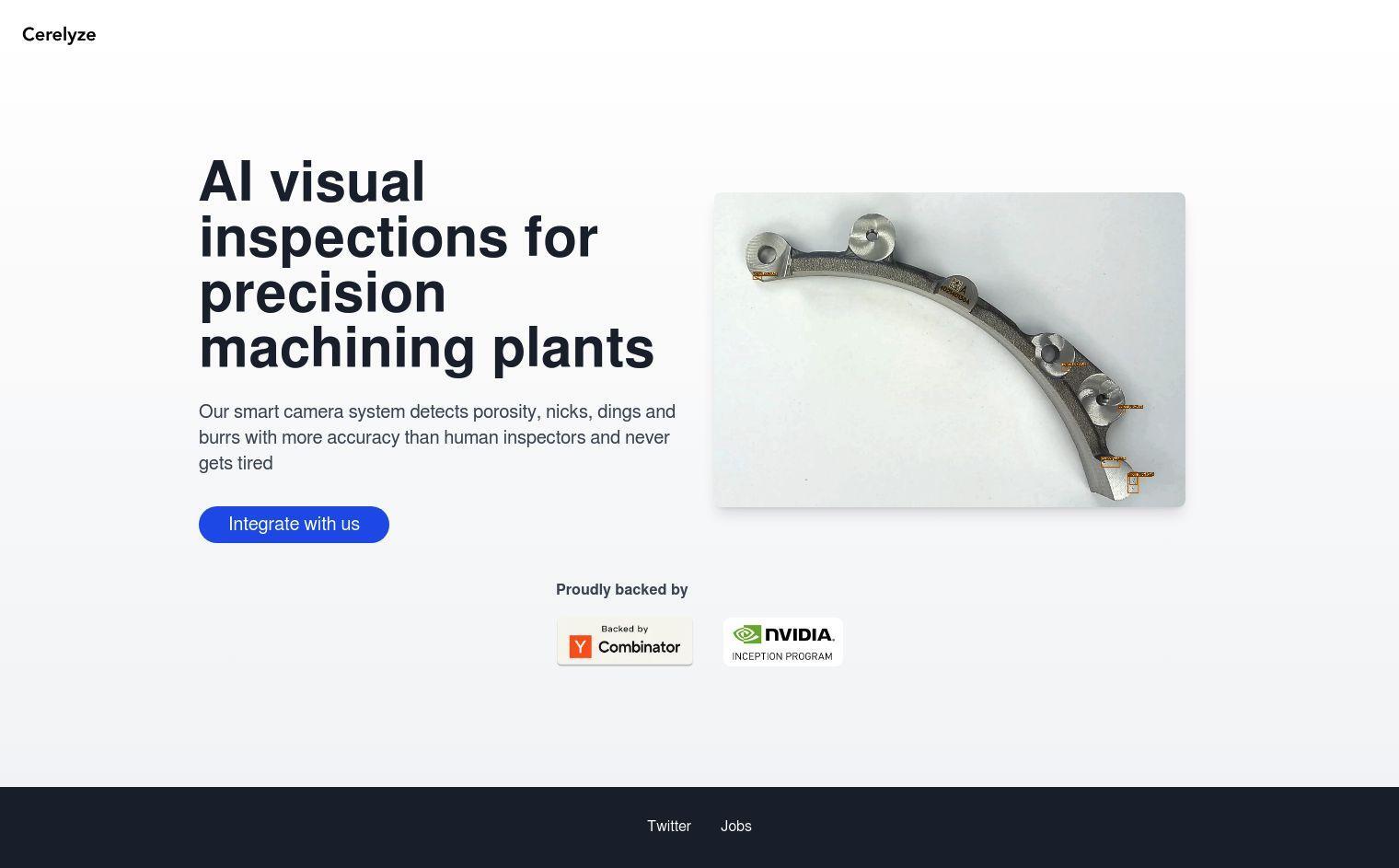

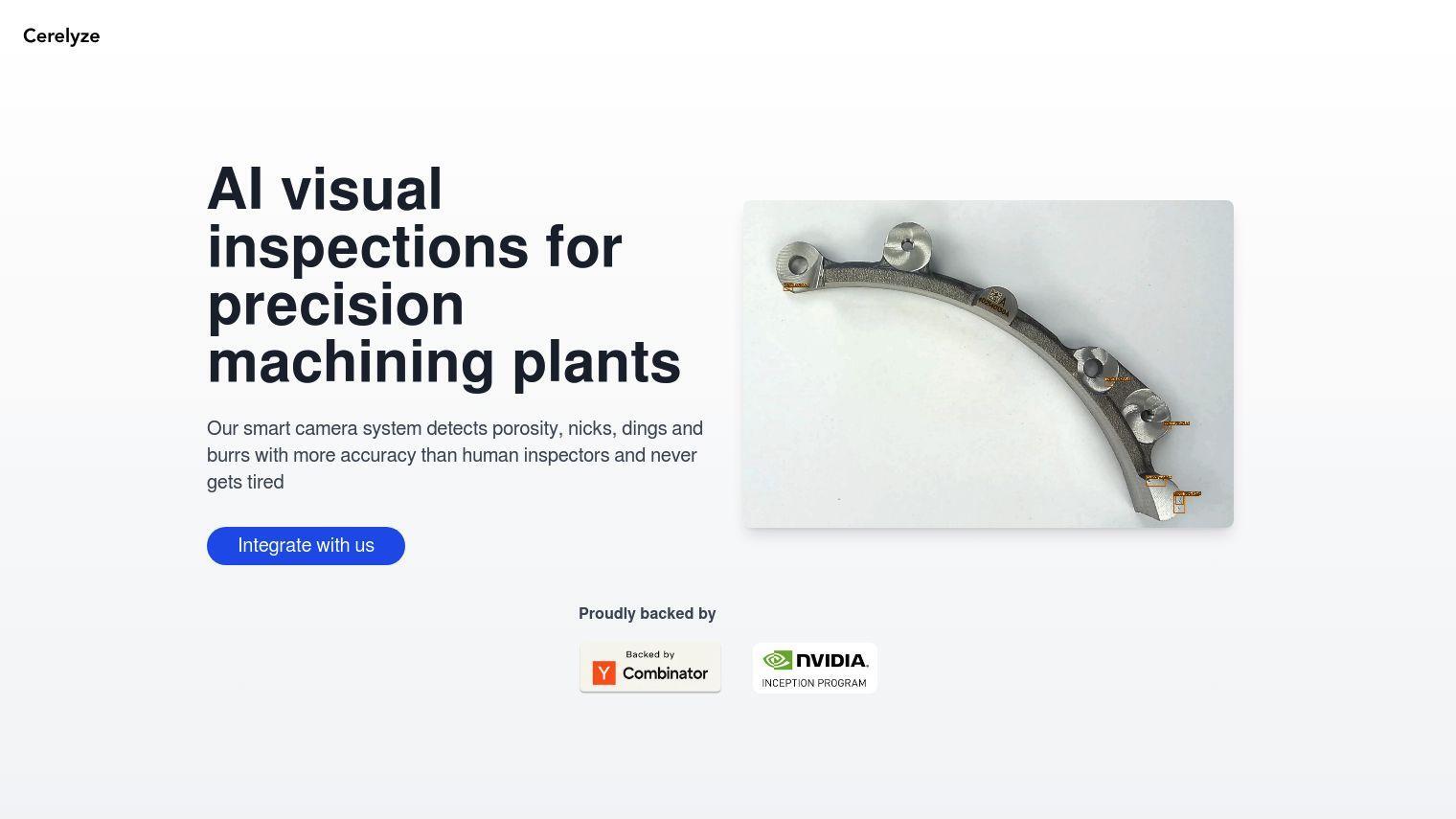

Cerelyze is an AI-based visual inspection tool for metal machining plants. It uses a smart camera system to spot defects like porosity, nicks, dings and burrs more accurately than human inspectors. The system helps ensure consistent quality control by minimizing human error and fatigue. The technology can help precision machining plants maintain quality standards that are critical to their operations, especially in industries where defects can be costly. Cerelyze's automation also helps eliminate downtime caused by manual inspection.

ASSISTANT: Cerelyze is an AI-based visual inspection tool designed for metal machining plants. It utilizes a smart camera system to detect defects such as porosity, nicks, dings, and burrs with higher accuracy than human inspectors. The system ensures consistent quality control by reducing human error and fatigability. This technology helps precision machining plants maintain high standards of quality in their products, which is particularly important for industries where defects can have significant consequences. Cerelyze's automation capabilities streamline the inspection process, increasing efficiency and reducing potential downtime.

Published on June 14, 2024

Related Questions

Tool Suggestions

Analyzing Cerelyze...