Question: Can you recommend a quality control solution that uses AI to detect defects in metal parts?

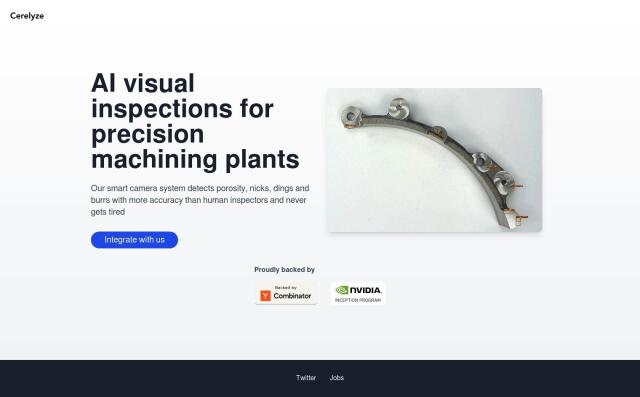

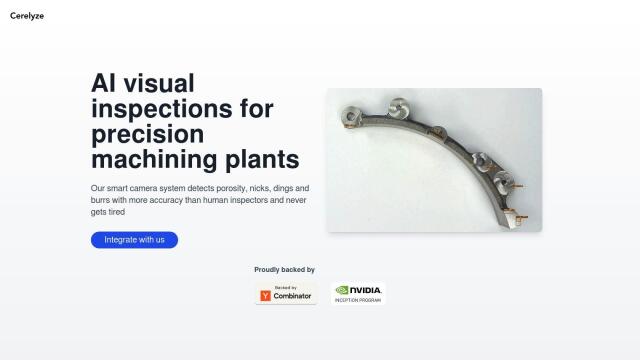

Cerelyze

If you need a quality control system that uses AI to spot defects in metal parts, Cerelyze is a good example. The system uses a smart camera to spot defects like porosity, nicks, dings and burrs with high accuracy, matching human inspectors. Consistent quality control is ensured by minimizing human error and fatigue while automating the inspection process, so you can get products out the door faster and avoid downtime.

Cognex

Another example is Cognex, which makes a variety of machine vision and barcode scanning products. Its In-Sight L38 is a 3D vision system that uses AI to automate 3D inspection and measurement tasks, helping to improve product quality and guide assembly robots. Cognex products are designed to meet a variety of industrial needs, so it's easier for companies to make products that are defect-free and to do so faster and at lower cost.