Question: I'm looking for a way to reduce human error in our inspection process, do you know of any automated visual inspection tools?

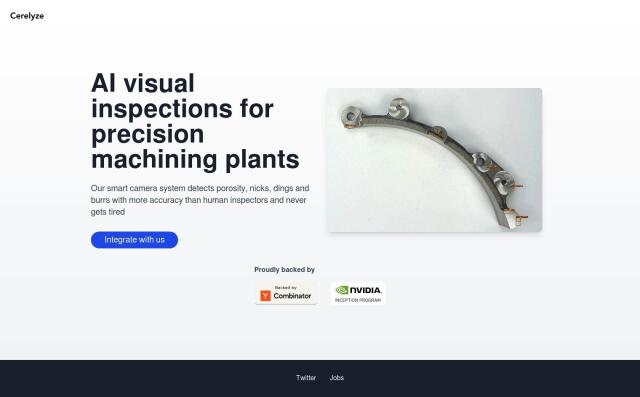

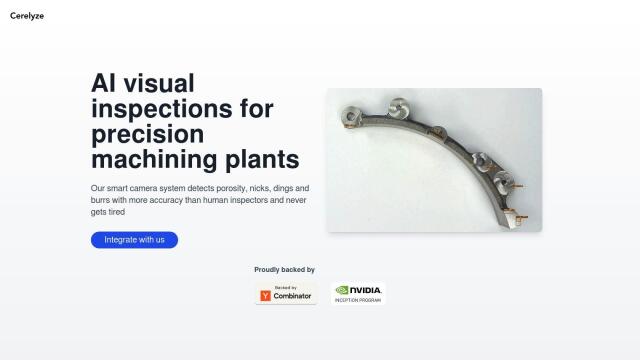

Cerelyze

Cerelyze is an AI-based visual inspection system for metal machining plants. It uses a smart camera system to detect defects like porosity, nicks, dings and burrs more accurately than human inspectors. Because it automates the inspection process, Cerelyze ensures consistent quality control, cuts out human error and fatigue, and boosts productivity, all factors that are important in industries where defects can be catastrophic.

Cognex

Another good option is Cognex, which makes a range of machine vision and barcode scanning products. Its In-Sight L38 is a 3D vision system that uses AI to accelerate and simplify 3D inspection, measurement and guidance tasks. That can help improve product quality, guide assembly robots and track products through manufacturing and distribution channels, and ultimately cut defects and costs in industries like manufacturing, logistics and automotive.

LandingLens

For a more general-purpose solution, LandingLens is a cloud-based computer vision software foundation that uses Large Vision Models and deep learning to handle a broad range of challenges. Customers can build and train their own models using proprietary imagery, and it can be deployed in different ways. That can help speed up processes, improve model performance and ensure reliable results across many industries.