Question: Can you suggest a software that provides real-time insights on machine operations and maintenance to improve productivity?

MachineMetrics

If you're interested in software that offers real-time insights into machine operation and maintenance to boost productivity, MachineMetrics is a good option. It links real-time production and operations data to provide insights so you can optimize asset uptime, capacity and maintenance costs. The software includes a range of tools, including historical trend analysis, so you can see your operations from all angles and make data-driven decisions.

Viam

Another option is Viam, a cloud-based platform that makes it easier to build, monitor and manage smart machines. It includes AI abilities, predictive fleet maintenance and a unified view of all machines. Viam can gather real-time and historical telemetry data, identify diagnostic problems and apply fixes, so it can be used in a variety of industries and situations. Its open-source design lets developers build smart machines with any hardware or software, and it's designed to improve operational efficiency and speed up developer velocity.

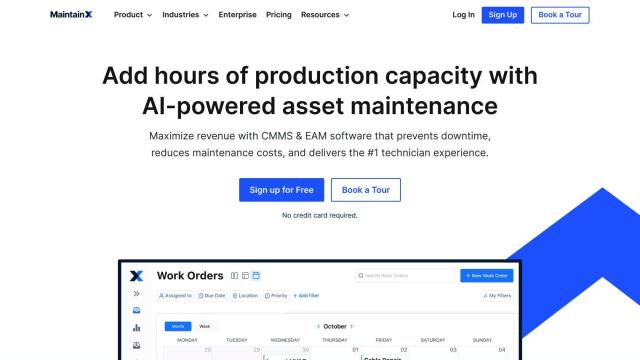

MaintainX

For a maintenance-focused option, MaintainX is an all-purpose platform that uses AI to optimize asset maintenance. It automates maintenance work with tools like work order management, condition-based maintenance and integration with IoT sensors. MaintainX is designed to minimize downtime and maintenance costs, so it's good for companies of any size with lots of equipment and facilities.

Auredia

Also worth a look is Auredia, a data analytics and AI software package that offers visualized data insights into machine operation and maintenance. It ties together many different parts of the shop floor and supply chain, using blockchain technology to ensure data integrity. Auredia's AI tools include operator performance improvement and predictive maintenance analytics, so it's good for plant managers looking to optimize operations and improve profitability.