Question: How can I increase productivity and reduce labor costs in my industrial setting, are there any autonomous vehicle solutions?

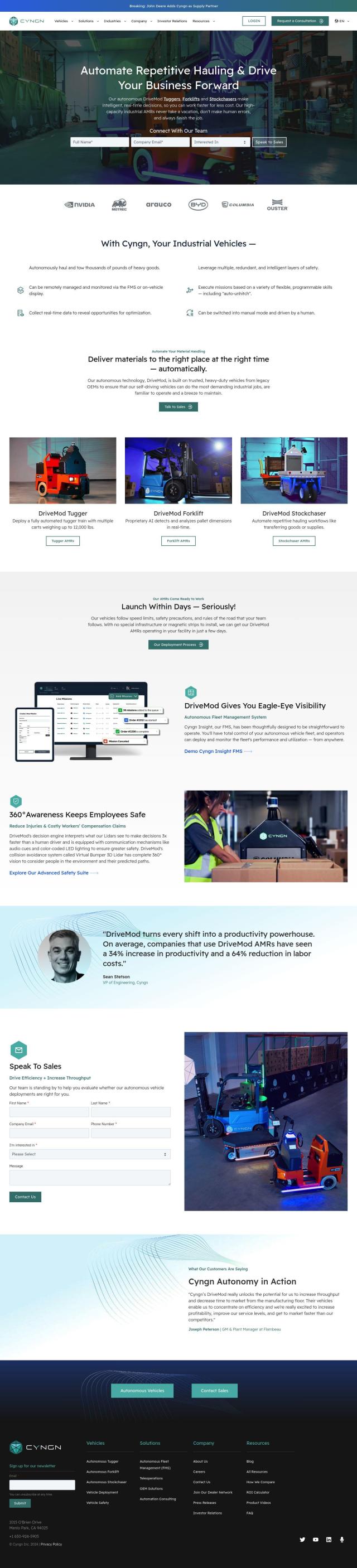

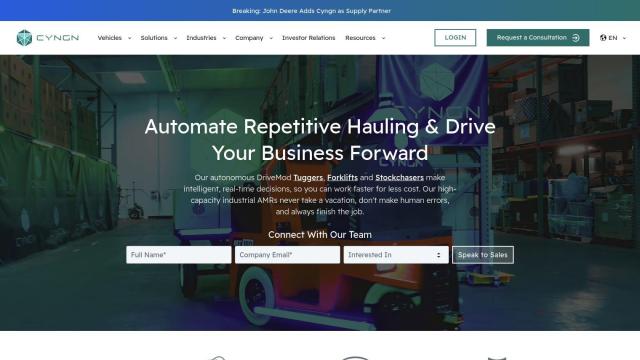

Cyngn

To cut labor costs and boost productivity in your industrial operation, there are a number of autonomous vehicle options that can help. One good choice is Cyngn, which makes self-driving forklifts and tuggers that can handle heavy loads on their own but can be switched to manual control if needed. The Fleet Management System (FMS) or in-vehicle display lets you dispatch and monitor them in real time, and the technology is based on established OEM platforms. The result: a 34% boost in productivity and a 64% cut in labor costs.

AIM

Another option is AIM, which can turn existing heavy equipment into fully autonomous machines. The system, which combines machine learning and robotics, can run 24/7 to boost productivity and safety in the construction and mining industries. AIM supports a range of heavy equipment, including skid steer loaders and excavators, and keeps ground personnel out of harm's way with 360-degree safety features. That can help you upskill employees and let them focus on higher-value work.

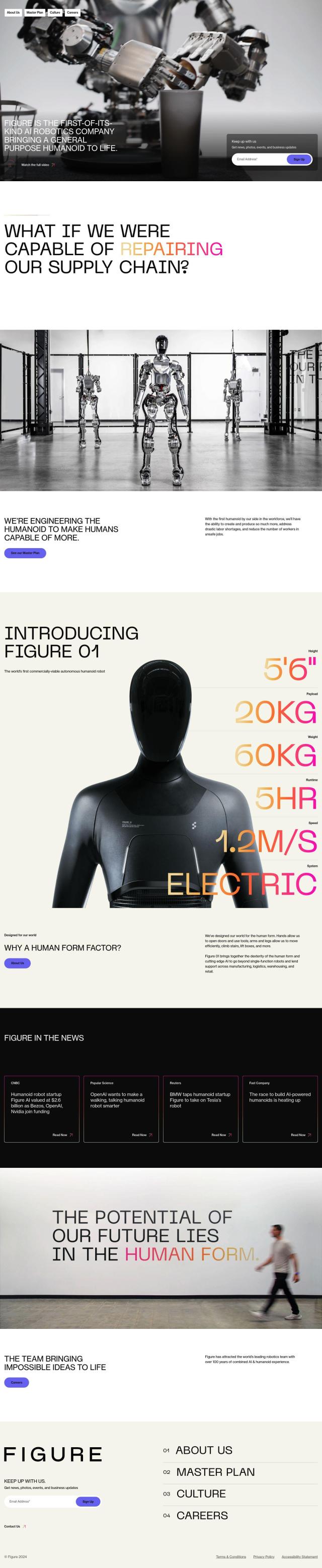

Figure

If you need a humanoid robot to do some work in manufacturing, logistics, warehousing and retail, Figure could be a good option. Figure 01 can open doors, use tools and lift boxes, helping to ease labor shortages and lower labor costs. With its AI technology, Figure hopes to increase productivity and improve safety in a range of industries.

Geotab

For a more general fleet management and optimization, check out Geotab. Geotab's GPS fleet tracking and management system uses AI and data intelligence to provide insights and recommendations. It can cut costs by automating processes, improve safety with AI video-based safety intelligence, and improve sustainability by monitoring and reducing fuel consumption and emissions. With more than 50,000 customers around the world, Geotab is a well-established and all-purpose fleet management option.