Question: I'm looking for a way to automate heavy equipment to reduce human error and improve efficiency, do you know of any options?

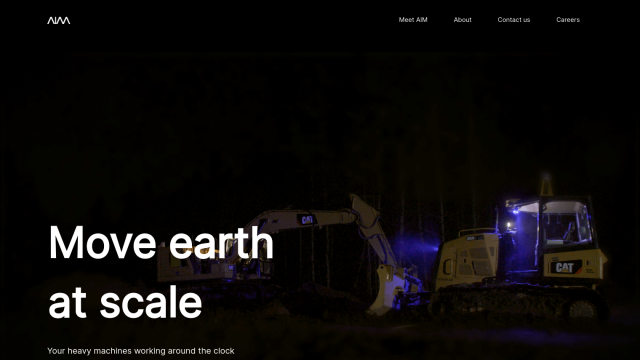

AIM

If you want to automate heavy equipment to cut down on human error and boost productivity, AIM is a good option. AIM turns existing heavy equipment into autonomous machines, boosting productivity and safety for construction and mining operations. It combines machine learning and robotics to run 24/7, even in rain or snow, and has 360-degree safety features to avoid collisions. The system can be retrofitted to a variety of earthmoving machines and still be operated manually so employees can work on higher value tasks.

Geotab

Another contender is Geotab. Although its main business is GPS fleet tracking and management, Geotab's system uses AI and data intelligence to optimize fleet operations. It offers features like fleet productivity tracking, AI-powered fleet safety and compliance automation. Geotab's technology can help lower costs, improve safety and boost sustainability by reducing fuel consumption and emissions. With decades of experience and thousands of customers, it's a well-established fleet management option.

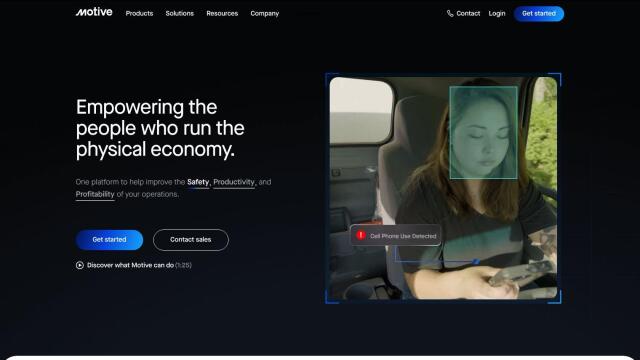

Motive

If you need a platform that handles fleet management and equipment monitoring, Motive could be a good fit. Motive uses AI-powered automation to improve fleet performance, safety, productivity and profitability. It offers features like driver safety alerts, fleet operations insights, equipment health monitoring and spend management. The platform is designed to support complex operations in industries like construction and logistics.

Polymath Robotics

Last, Polymath Robotics has an autonomous navigation platform for industrial off-highway vehicles. It's vehicle-agnostic and offers features like waypoint navigation, path planning, obstacle detection and a safety layer that can stop the vehicle automatically. It's designed to be easy to use and integrate with existing software, so it's a relatively simple way to automate your fleet even if you don't have robotics expertise.