Question: Can you recommend a solution that can help alleviate labor shortages in industries such as manufacturing and logistics?

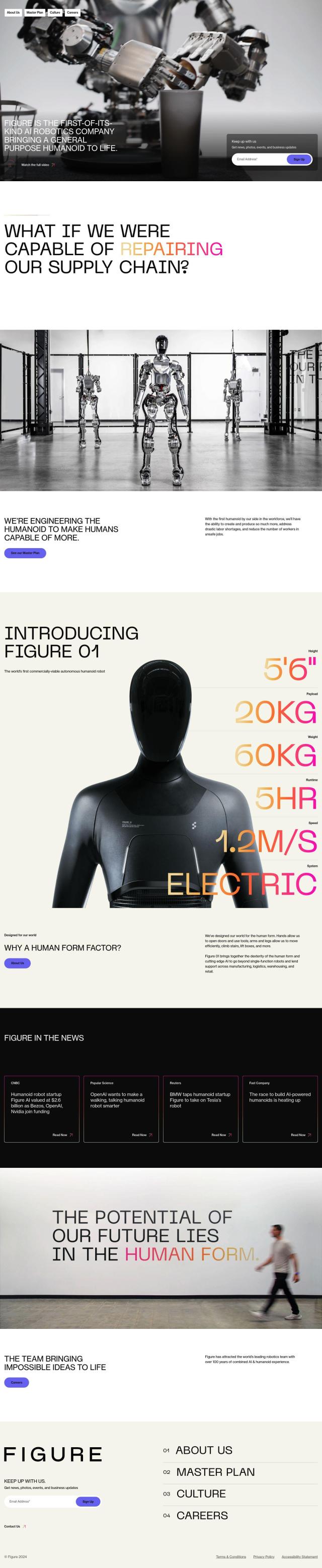

Figure

Figure is working on an autonomous humanoid robot called the Figure 01 that's designed to help companies with manufacturing, logistics and warehousing. The robot can open doors, use tools, navigate, climb stairs and lift boxes, so it's a general-purpose option for reducing labor requirements and increasing productivity. Figure has more than 100 years of experience in AI and humanoids, and its goal is to increase productivity, reduce labor costs and improve work safety.

Quinyx

Another option is Quinyx, a cloud-based, mobile-first AI-powered Workforce Management Platform. It includes features like demand forecasting, workforce scheduling, labor optimization and time and attendance management to help companies work more efficiently and cut labor costs. Quinyx is designed for a variety of industries, including retail, warehousing and delivery, and integrates with existing payroll systems, so it's a powerful option for managing and optimizing workforces.

GXO

For logistics and supply chain work, GXO offers customized solutions with a big push on automation and data analysis. The company has more than 970 warehouse sites in 27 countries and has improved productivity with the use of robots and machine learning. GXO's full range of services could help companies improve their operations and get ahead in managing their supply chains.

Dozuki

In the manufacturing industry, Dozuki has a connected worker platform that includes standardized work instructions and training software. The platform increases productivity and performance by lowering employee turnover and changeover times. It's available in more than 100 languages and spans many industries, so it could be a good option for improving operations.