Question: Can you suggest a robotic system that improves workplace safety and productivity?

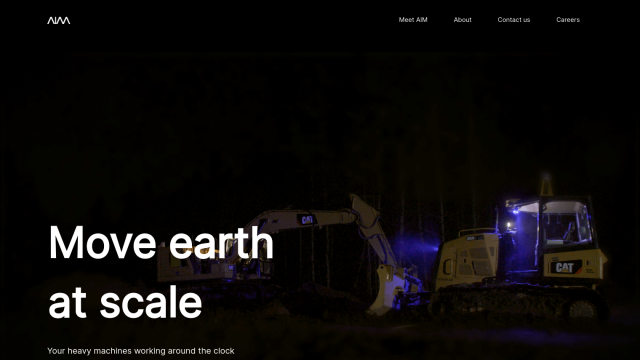

AIM

If you're looking for a robotic system to boost workplace safety and productivity, AIM is worth a look. AIM is a system that turns existing heavy equipment into fully autonomous machines, boosting productivity and safety in construction and mining. It uses machine learning and robotics technology so it can run 24/7 without a human operator, and it has multiple safety features to protect people on the ground. It can be used to retrofit a range of earthmoving machines, and it lets employees concentrate on higher value tasks like planning the site.

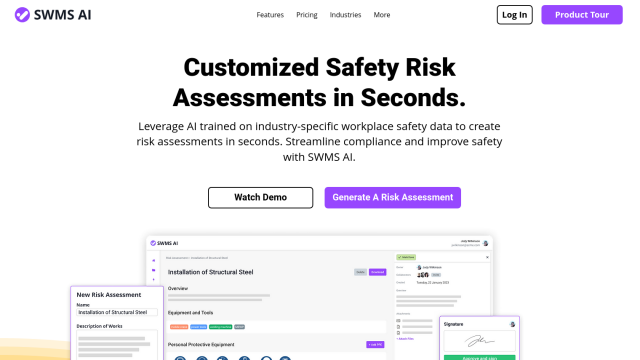

SWMS AI

Another interesting project is SWMS AI, an AI-based information system for safety compliance and risk assessment. The system automates and optimizes safety management tasks, improving workplace safety and productivity through customizable safety compliance and risk assessment tools. It's designed to be integrated into existing workflows and safety management systems, so it's adaptable for a wide range of companies.

Cyngn

For material handling, Cyngn has autonomous industrial vehicles like forklifts and tuggers that can autonomously pull and push heavy loads. The vehicles have multiple layers of safety and can be put into manual mode for human operation. The technology improves material handling and cuts labor costs, making workplaces safer and more productive.

Berkshire Grey

Berkshire Grey also offers AI-based enterprise robotics to automate manual supply chain operations. Its options include robotic put wall, pick, package sortation and mobile options that can dramatically reduce labor requirements and boost productivity. The technology can be easily integrated with existing warehouses and offers a fast return on investment through lower fulfillment costs.