Question: Do you know of a system that offers advanced IoT-based solutions for asset management and predictive maintenance in industrial settings?

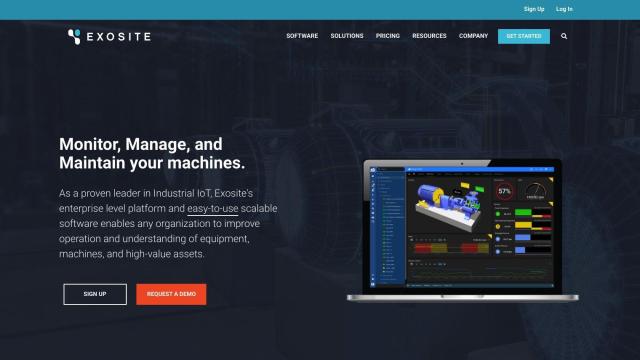

Exosite

If you're looking for a more sophisticated IoT-based solution for asset management and predictive maintenance in industrial settings, Exosite is a good option. The platform lets you monitor equipment conditions remotely, manage assets and perform maintenance, so you can predict maintenance needs, warn operators of serious operating conditions and optimize operations. It offers real-time equipment visualization, condition monitoring and customizable rules for optimizing service and maintenance. Exosite is highly scalable and secure, with a variety of deployment options including cloud infrastructure, managed dedicated cloud and on-premise hosting.

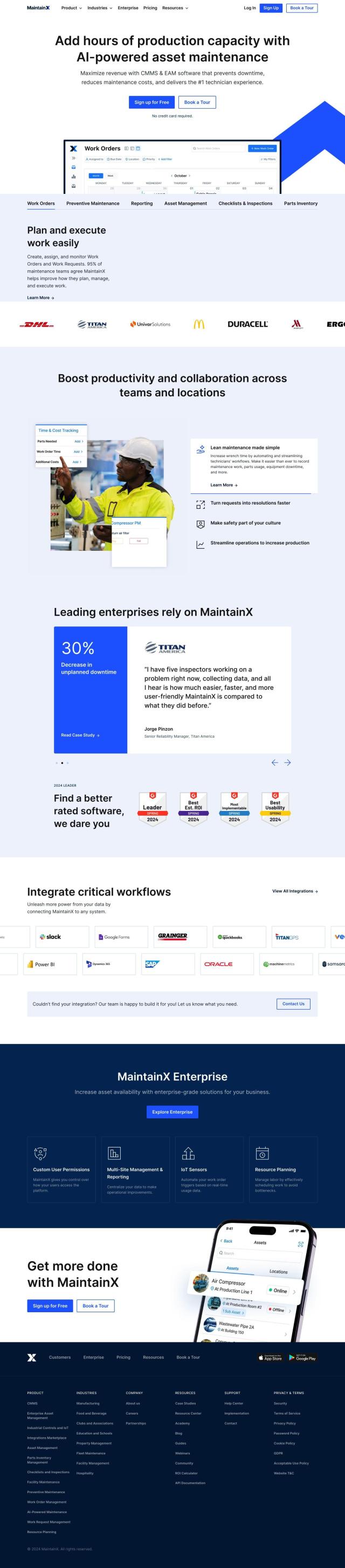

MaintainX

Another contender is MaintainX, which uses AI to optimize asset maintenance. The platform automates maintenance workflows through features such as work order management, preventive and predictive maintenance, inventory management, and customizable dashboards and reporting. MaintainX supports IoT sensor integration, automated maintenance triggers, and flexible implementation options to accommodate different business needs, all designed to improve productivity and reduce downtime and maintenance costs.

KCF Technologies

If you're looking for a more comprehensive machine health optimization, check out KCF Technologies. This platform is geared for manufacturing industries and includes ruggedized sensors, advanced analytics through SMARTdiagnostics, and elite engineer support. Among its features are mesh networking, wireless vibration sensors, and IoT HUB for complex asset health monitoring. KCF Technologies offers a risk-free guarantee and is designed to improve safety and efficiency, so it's a good fit for industries like Oil and Gas, Automotive, and Forest Products.

MachineMetrics

Last, MachineMetrics connects real-time production and operations data to deliver actionable insights for factory workers and operations leaders. The platform is designed to maximize asset uptime, reduce maintenance costs and improve efficiency through data-driven decisions. It offers a modern API for integrating real-time machine data with existing factory software stacks and offers a variety of tools to automate workflows and improve planning, making it a good fit for factories of all sizes.